Peanut Blancher

The Significance of Peanut Blanching Process

Revolutionize Your Peanut Processing with Our Advanced Peanut Blanchers

The significance of peanut blanching is mainly reflected in 4 aspects: 1) improving the taste of peanut products, 2) enhancing nutritional value, 3) increasing economic value, and 4) achieving product diversification.

Improve taste: peanuts are leguminous crops, containing about 50% lipids, 25% protein, 25% vitamin B1, vitamin B2 vitamin E, and other vitamins. The peanut shell is basically removed during the primary cleaning process. The red skin contains a certain bitterness. After the peanuts are blanched, this bitterness can be removed, making the peanuts more delicious and more suitable for direct consumption or for making various snacks.

Enhance nutritional value: although peanut skins are rich in nutrients, including antioxidants, some people may have allergic reactions to certain ingredients in peanut skins. After blanching, the risk of allergic reactions can be reduced, while allowing consumers to better absorb the nutrition of peanuts.

Increase economic value: peanuts, as a major economic crop, are widely planted around the world and are one of the main raw materials for common snacks. Peanuts are blanched and then exported, which increases the product yield and strengthens the competitiveness of peanut processors in international trade.

Achieve product diversification: blanched peanuts are suitable for making various foods, such as chopped peanuts, diced peanuts, peanut powder, fried peanuts, salted peanuts, peanut cakes, peanut candy, peanut milk, peanut butter, peanut protein powder, and various pastry fillings, etc., to meet the needs of different consumers.

Peanut blanching process is a process in which most peanut processing companies need to be involved. It is roughly divided into 2 categories according to different processing methods, one is dry peanut blanching machine and the other is wet peanut peeling machine. Today we will introduce you to 4 types of blanching machines. Please click on the navigation bar on the right according to your needs to quickly lock in and get the information you need.

I.Air Peanut Blancher

Air Peanut Blancher

Recommendation index

The new Air Peanut Blancher Machine is a breakthrough technological innovation in the peanut processing industry. It has changed the problem of blanched peanut surface wear that cannot be solved during peanut blanching production.

Application:

Peanut Kernels (uniformed size)

Long shape: 24/28,28/32,34/38,38/42,45/55

Round shape: 25/35,35/40,40/50,50/60,60/70 80/100

Hazelnuts (uniformed size)

Size: 11mm,12mm, 13mm, 14mm,15mm,16mm, 17mm

Blanching Media: compressed air

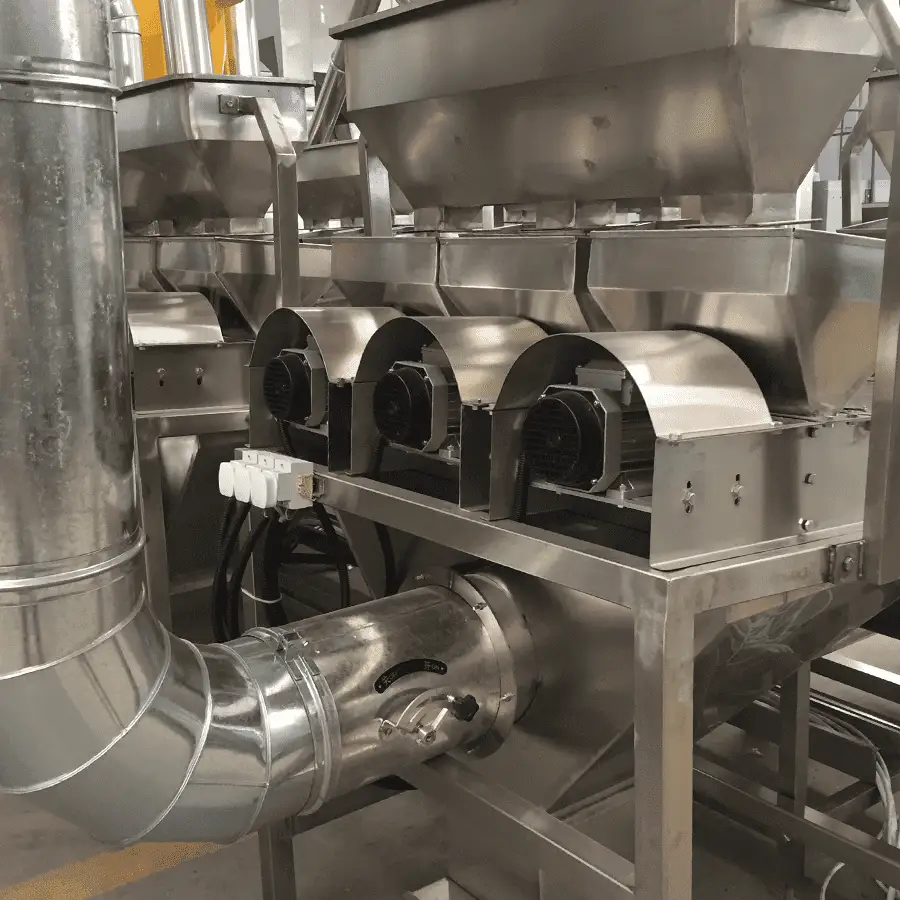

The air peanut blancher machine uses compressed air as the main blanching force, replacing the traditional sand rollers blancher machine. This innovative design improves the blanching efficiency and significantly reduces mechanical wear and blanched peanut surface polishing. The equipment consists of multiple modules to ensure the automation and efficiency of the entire blanching process.

Main components:-

1. Hopper: used to store peanuts to be processed. The design of the hopper can ensure uniform feeding of peanuts, avoid blockage, and improve blanching efficiency.

2. Z Bucket Elevator: equipment that transports peanuts from the hopper to the blancher machine to ensure that the peanuts enter the next process smoothly.

3. Receiving Bin: used to receive slight roasted peanuts, reducing secondary contamination of materials.

4. Automatic Weighing Device: The peanuts are accurately weighed before entering the air blancher machine to ensure that the quantity of peanuts processed each time is consistent, thereby ensuring the stability of the blanching effect.

5. Air Blanching Device: The core part uses the airflow generated by compressed air to quickly separate the peanut red skin from the peanut kernel. Unlike traditional mechanical friction, air blancher reduces damage to the peanut kernel and improves the yield rate.

6. Red Skin Suction Device: Through strong adsorption force, the separated peanut red skin is quickly collected to ensure the cleanliness of the working environment and the purity of the product.

7. Discharge Vibration Sifter: The vibrating screen is used to screen and transport the blanched peanuts to ensure the integrity of the peanut kernels.

8. Air Compressor: provides compressed air required for blanching. Users can configure it according to their needs to ensure the stability and efficiency of the equipment.

5 Major Systems Of The Whole Set Of Air Blanching Equipment:

1. Feeding System: includes hoppers and elevators to ensure continuous supply and smooth transmission of peanuts.

2. Blanching System: The core blanching device uses compressed air for efficient blanching.

3. Red Skin Collection System: specially used to collect the red skin of blanched peanuts to avoid secondary pollution.

4. Discharging System: The vibrating screen ensures the smooth discharge of blanched peanut kernels and peanut germs.

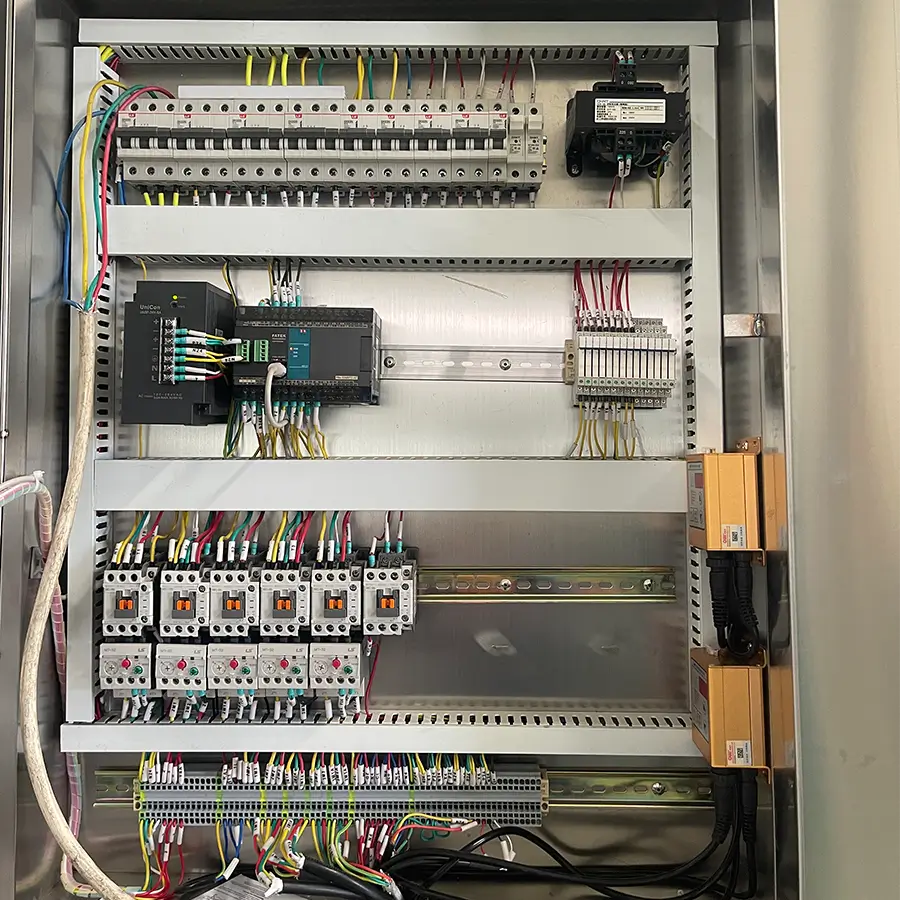

5. PLC Control System: Programmable logic controller is used for automatic control to ensure accurate operation and safe operation of the entire production process.

Advantages and Features:

– Efficient Blanching: Air blanching technology is more efficient than traditional sand roller peanut blancher machines, and less damage to peanut kernels and a high yield rate.

– Energy Saving and Environmental Protection: Compressed air is used as the power source, which reduces power consumption and equipment wear. At the same time, the dust removal device can effectively reduce dust pollution in the production environment.

– High Degree of Automation: PLC realizes automatic control of the entire peeling process, reduces human intervention, and reduces operation difficulty and maintenance costs.

– Easy Maintenance: The modular design makes daily equipment maintenance easier, reducing equipment downtime and maintenance costs.

The new air peanut peeling machine is suitable for peanut processing enterprises of all sizes, especially those with high requirements for product quality and production efficiency. Through this equipment, the efficiency of peanut blanching and the market competitiveness of products can be significantly improved.

Technical Parameter

Capacity: 500-750kg/hr

Power: 3.5kw

Blanching Rate: ≥ 98%

Split Rate: ≤ 25%(long peanuts)

≤ 30%(round peanuts)

Blanching Moisture: 4.5-5%

Compressed Air Consumption: 360m3/hr

Air Pressure: 0.7~0.8Mpa

Power: 22~37kw (suggested air compressor)

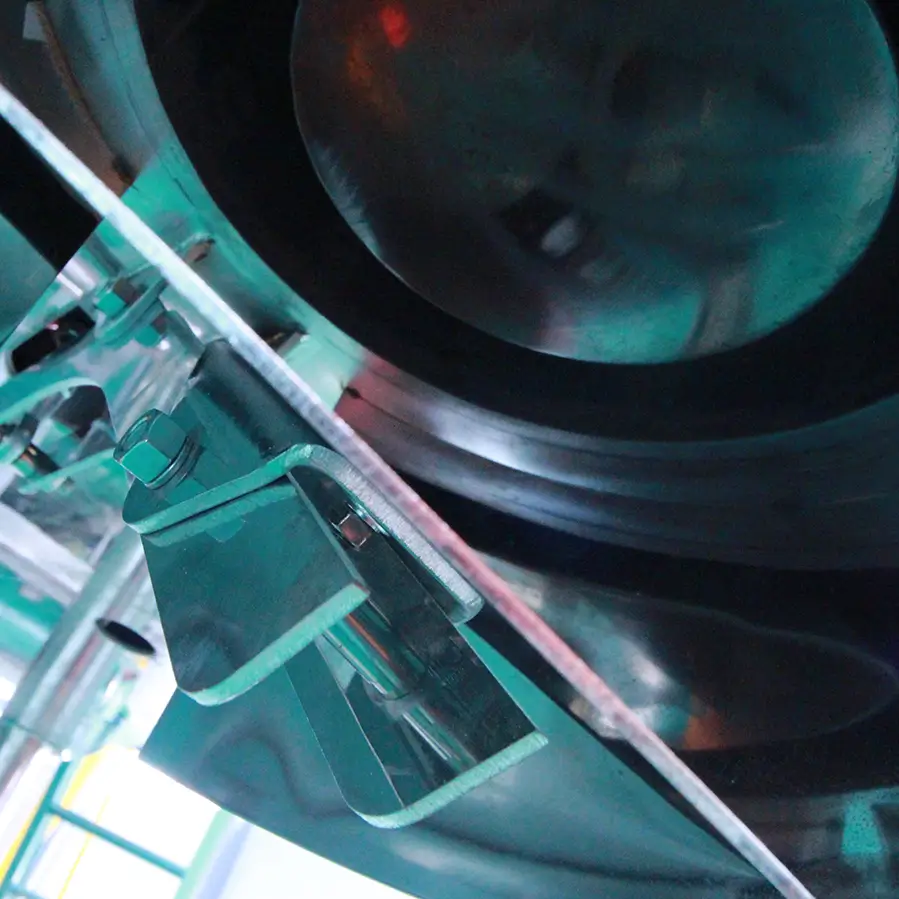

Air Peanut Blancher Machine Gallery

Choosing a proper peanut blanching machine is very important, good quality blanched peanuts bring more profit on the finished products, as a peanut manufacturer, you know it more deeply than anyone.

Frequently Asked Question

Let Us Know, Whatever You Need for Air Peanut Blanching Machine

Does the air peanut blancher treat peanuts hot or cold?

Air peanut blancher works in ambient temperature, which means the peanut is in normal air temperature, not hot, not cold.

What is the proper value of moisture of the peanuts kernels?

moisture content is 4%, it’s proper moisture for premium blanching. Depends on different processing purpose, moisture can be more or less, but keep the range between 4-6%.

How the compressed air remove the peanut skin?

The peanuts feeding method is quantitative weighing to ensure Each batch weight is consistent. When the peanuts fall into the air blancher chamber, the compressed air produces an instantaneous release of wind force. The wind force makes the peanuts rotate 360 degrees in the blanching chamber. Under the action of high-pressure wind, the peanut red skin peels off in a short time to complete the peeling process, then fall down to the bottom, red skin is sucked out of blancher, collected by air cyclone which is installed outside of the workshop. There are numerous air inlet holes on the circumference of the peeling chamber. High-pressure air enters the peeling chamber through these holes to complete peeling.

How can we control and adjust the blanching time?

Through the air peanut blancher PLC screen, you can adjust the blanching time easily.

How do we clean the air peanut blancher? Include the inside of the machine?

Use an air gun, open the bottom discharge cover, from bottom to top, clean the blanching chamber, separating chamber, connect pipe step by step.

II.Split Peanut Blancher

Split Peanut Blancher

Recommendation index

Split Peanut Blancher is designed to split & blanch roasted peanut kernels into half or less half piece. It also called a Belt Blancher. Due the character of structure, this peanut blancher can also make broken roasted peanuts.

Application:

Peanut Kernels (uniformed size)

Long shape: 24/28,28/32,34/38,38/42,45/55

Round shape: 25/35,35/40,40/50,50/60,60/70 80/100

Overview

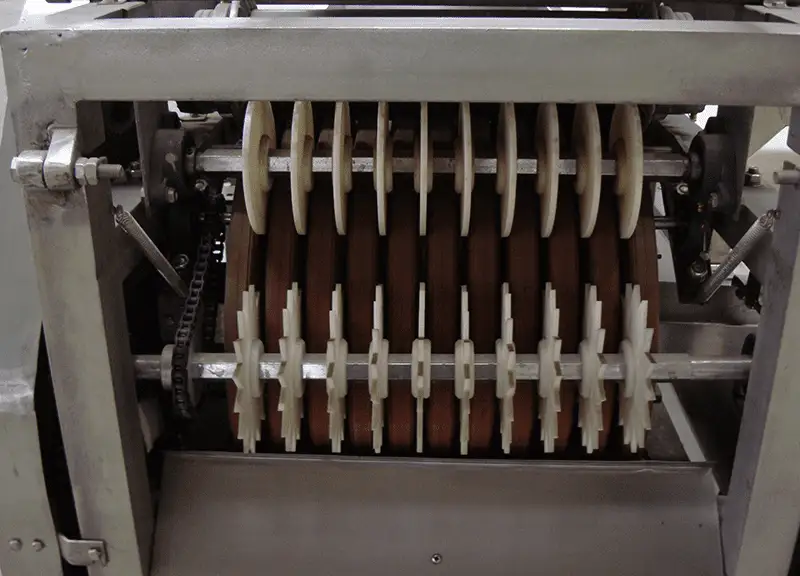

The Split Peanut Blancher, also known as a Belt Blancher, is a specialized machine designed for splitting and blanching roasted peanut kernels into halves or smaller pieces. This machine splits the peanuts and removes the red skins, making it a crucial piece of equipment in peanut processing lines, particularly in peanut blanching, chopping, butter, and slicing production lines.

Working Principle

The machine is roasted peanuts kernels enter the feeding hopper and pass through the vertical conveyor, to the gap between the two silicone belts with special strips with special textures, the gap between the silicone strips can be adjusted according to needs. The two silicone strips continuously rub peanut kernels at a high-speed rotation. So that the peanuts are broken and peeled, while the feed spiral pushes the peanuts forward and then falls on the vibrator. Through the vibration screening of the vibrator, the suction fan continuously sucks away the peanut red clothes, thereby achieving the separation of the peanut kernels and the red clothes.

Key Features and Functions:

1. Splitting and Blanching:

The primary function of the Split Peanut Blancher is to split roasted peanut kernels into 1/2 or less than 1/2 pieces. The machine efficiently handles the splitting process, ensuring a consistent size and quality of the split peanuts.

2. Red Skin Removal:

During the blanching process, the red skins are removed from the peanuts. These skins are then collected using an air cyclone system, ensuring a clean and efficient removal process. This feature is particularly beneficial when processing peanuts from peanut sellers, which may already contain broken kernels.

3. Versatility in Processing:

The machine is highly versatile and can be adjusted to meet different processing requirements. By altering the gap between the rubber belts, operators can achieve the desired level of splitting and blanching, making it adaptable to various peanut processing lines, including peanut chopping, butter, and slicing lines.

4. Bitter Germ Removal:

After the blanching process, bitter peanut germs are effectively removed by a vibrating sifter located at the back of the blancher. This ensures that the final product is of high quality, and free from undesirable flavors.

5. Complete System Design:

The Split Peanut Blancher system includes a bucket elevator, blanching machine, and air cyclone, creating a fully integrated solution for the blanching process. The system is available in two configurations: full stainless steel for maximum durability and hygiene, or a combination of stainless steel contacting parts with a painted carbon steel frame for cost-effectiveness.

6. Applications:

This split blancher is a key component in peanut processing plants, particularly for producing split-blanched peanuts that are used in various products such as slivers, dice, slices, and peanut butter. It ensures that the peanuts are properly prepared for further processing, enhancing the quality and consistency of the final product.

Expanded Benefits and Applications:

– Quality Enhancement: The Split Peanut Blancher significantly improves the quality of split peanuts by ensuring uniform size and removing any unwanted skins and bitter germs. This results in a superior product that meets the food industry’s demands.

– Efficiency and Automation: By integrating this blancher into your production line, you can achieve a higher level of automation and efficiency, reducing manual labor and increasing output.

– Flexibility: The machine’s adjustable settings make it suitable for various peanut processing applications, allowing manufacturers to produce a wide range of peanut products with consistent quality.

– Durability and Hygiene: The option to choose a full stainless steel construction ensures that the blancher is durable and easy to clean, meeting stringent food safety standards.

The Split Peanut Blancher is an essential piece of equipment for any peanut processing facility, offering reliable performance, versatility, and high-quality output. Whether you are producing peanut slivers, dice, slices, or preparing peanuts for butter production, this machine is an ideal choice to enhance your processing capabilities.

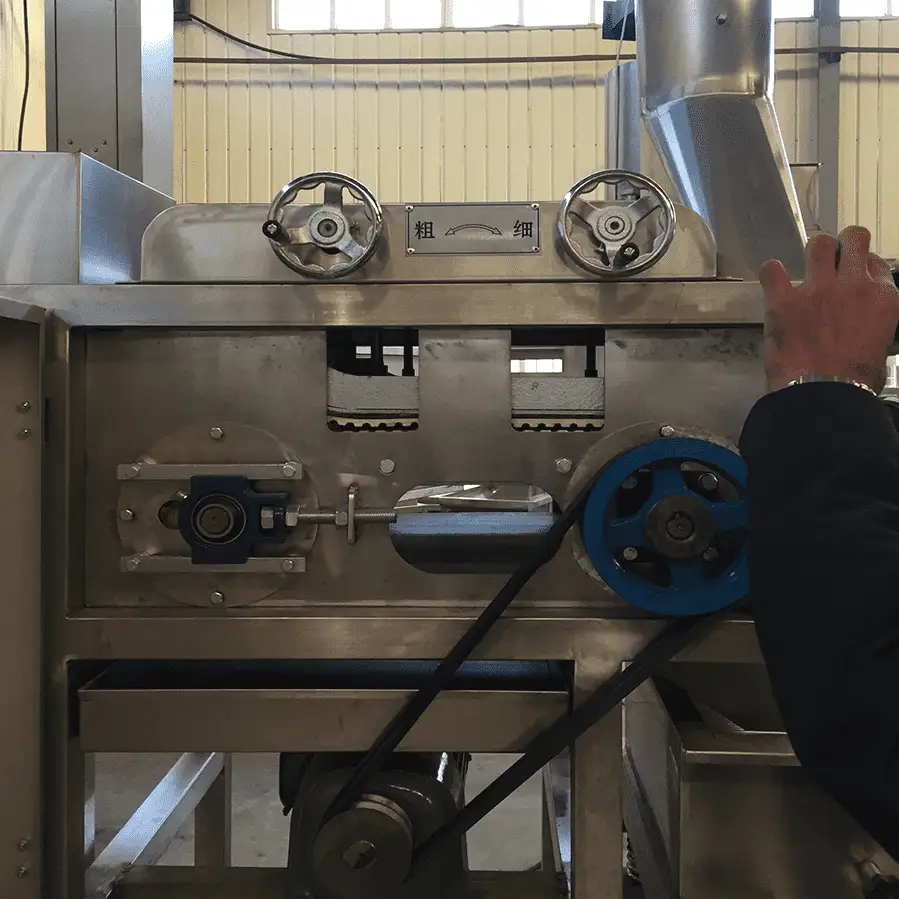

Technical Parameter

Capacity: 1000-1200kg/hr

Power: 5kw

Blanching Rate: ≥ 95%

Blanching Moisture: 2-5%

Dimension:1080 x 710 x 1850mm

Weight: 620kgs

Split Peanut Blancher Gallery

Blancher, Blanching Peanuts

The peanut blanching process is essential, splitting and blanching, occur during the blanching chamber

II.Whole Peanut Blancher

Whole Peanut Blancher

Recommendation index

The Whole Peanut Blancher enhances raw groundnuts by efficiently blanching roasted peanuts and hazelnuts with over 90% success. Its compact structure, stable performance, and low noise make it ideal for producing high-quality snacks and confectioneries.

Application:

Peanut Kernels (uniformed size)

Long shape: 24/28,28/32,34/38,38/42,45/55

Round shape: 25/35,35/40,40/50,50/60,60/70 80/100

Overview

Roasted whole peanut blanching provides substantial value addition on raw groundnuts. It can make ideal material for variety of snacks and confectionaries. The whole nut blancher designed by us, is a kind of advanced equipment for blanching roasted peanut and hazelnut kernels, it features compact structure, stable performance and low noise. Under ideal working condition, the blanching ratio can reach above 90%.

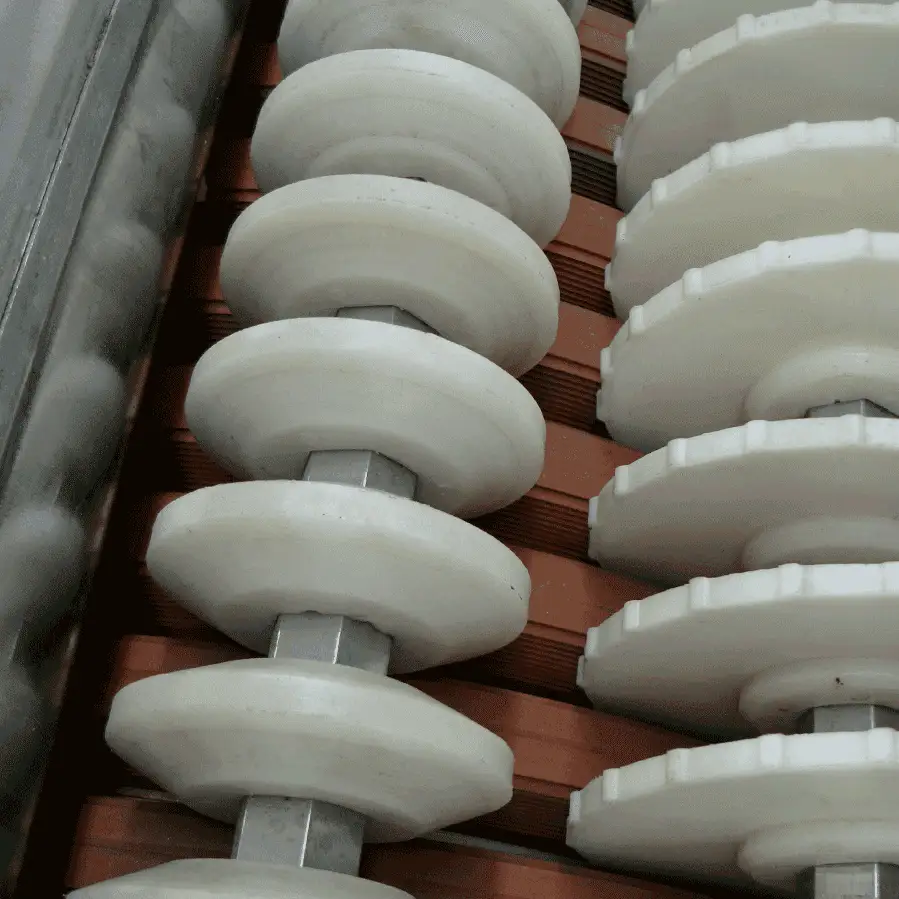

Working Principle

Light roasted peanuts come from vibrating discharge device, through bucket conveyor, are feed into blancher, after being put into charging spout, peanuts automatically enter into decorticating room which is composed of sand rollers, by the rotating and friction of rollers, the red skin will be taken, and sucked by the air cyclone, the white blanched peanuts will fall down at exit or fall down to the sorting belt.

In order to enlarge the capacity of peanut blanching, several peanut blanchers can be assembled together, customized service is available, welcome to tell us your idea on peanut blanching process.

Technical Parameter

Capacity: 200kg/hr

Power: 0.37kw

Blanching Rate: >90%

Blanching Moisture: <10%

Dimension:850 x 250 x 390mm

Weight: 220kgs

Whole Peanut Blancher Gallery

Blancher, Blanched Peanuts

The peanut blanching process is essential, splitting and blanching, occur during the blanching chamber.

IV.Wet Peanut Peeler

Wet Peanut Peeler

Recommendation index

The Wet Peeler Machine is essential high-efficiency equipment for wet peeling in the production of peanuts, broad beans, and almonds. It is versatile, serving not only in fried peanut and broad bean production lines but also in standalone operations such as almond beverage plants, fried flour-coated peanut processing, and various flavored snack factories. Its adaptability makes it ideal for producing a wide range of traditional and nutritious foods, ensuring high-quality output across diverse processing applications.

Application:

Peanut Kernels (uniformed size)

Long shape: 24/28,28/32,34/38,38/42,45/55

Round shape: 25/35,35/40,40/50,50/60,60/70

Almond (uniformed size)

Broad Bean (uniformed size)

Overview

The Wet Peanut Peeler Machine is a critical piece of high-efficiency equipment designed for the wet peeling of peanuts, broad beans, and almonds. Its versatility makes it indispensable across various food processing industries. This machine is not only an essential component in production lines for fried peanuts and broad beans but is also widely used in stand-alone operations such as almond beverage production plants, fried flour-coated peanut processing plants, and cumin peanut processing facilities. Additionally, it finds application in the production of marinated peanuts with unique flavors, almond and broad bean processing plants, and factories producing peanut vegetable pickles, flavored almonds, and various traditional and nutritious snack foods.

Key Features:

High Efficiency: The machine ensures rapid and thorough peeling of wet skins, significantly enhancing productivity.

Versatility: It is adaptable to a wide range of applications, from small-scale production to large industrial operations, making it suitable for various food processing plants.

Compact Design: The machine’s compact structure allows it to be easily integrated into existing production lines without requiring significant space.

Stable Performance: Engineered for reliability, it operates with minimal downtime, ensuring consistent output.

Advantages:

Improved Product Quality: The wet peeling process effectively removes skins without damaging the kernels, resulting in a smoother, higher-quality product ideal for further processing or direct consumption.

Energy Efficiency: The machine is designed to operate efficiently, consuming less power while delivering high output, which translates to lower operational costs.

User-Friendly Operation: With intuitive controls and straightforward maintenance requirements, the Wet Peanut Peeler Machine is easy to operate, reducing the need for specialized training and minimizing labor costs.

Broad Applicability: Its ability to process a variety of nuts and beans makes it a versatile tool that can adapt to the evolving needs of the food processing industry.

The Wet Peanut Peeler Machine is a versatile, efficient, and reliable solution for wet skin removal in various food processing applications. Its advanced design and user-friendly features make it an invaluable asset for manufacturers aiming to produce high-quality, peeled nuts and beans with consistent performance and minimal operational costs.

Technical Parameter

Model: GWB-250 wet peanut peeler

Capacity: 200-250kg/hr

Peeling ratio: 96-98%

Whole nut ratio: 85-95%

Power: 0.75kw

Size: 1080*850*1100mm

Weight:285kgs

Wet Peanut Peeler Gallery

Peeler, Peeled Peanuts

The peanut peeling process is essential, peeling off the skin and separating the skin and kernels occur during the blanching chamber

You Also May Like

Related Equipment

Let Us Know, Whaterver You Need

Dont Heistate To Ask Question

It is important to choose a proper machine for your blanched peanuts, we are the expected experts who listen to your request on the blanching process, and give our practical advice & solution.