Introduction

Wire mesh roasting belts are revolutionizing the way peanuts are roasted, making the process faster, more energy-efficient, and precise. By optimizing airflow and ensuring even heat distribution, these belts deliver perfectly roasted peanuts with unmatched crispness—all while reducing energy consumption.

Designed for both small-scale and industrial peanut roasters, wire mesh belts are durable, heat-retentive, and compatible with modern nut roasting equipment. They not only improve roasting efficiency but also help businesses meet sustainability goals without compromising flavor or quality.

Curious how this simple yet powerful innovation transforms peanut roasting? Let’s explore how wire mesh roasting belts combine precision, performance, and eco-friendliness to lead the industry into a smarter, greener future.

The Growing Demand for Efficient Peanut Roasting in Industrial Peanut Roaster Systems

In today’s competitive market, efficiency is everything, and the peanut roasting industry is no exception. With rising consumer demand for perfectly roasted peanuts and a growing emphasis on sustainability, industrial peanut roaster systems are under pressure to deliver consistent, high-quality results with minimal energy consumption. Businesses are seeking innovative solutions that can streamline production processes, reduce operational costs, and meet environmental standards—all without compromising the flavor or texture of the final product.

What Makes the Wire Mesh Roasting Belt a Game-Changer in Peanut Roasting Machines?

Enter the wire mesh roasting belt—a revolutionary component that’s transforming peanut roasting machines across the globe. Unlike traditional conveyor systems, wire mesh belts are engineered to enhance airflow control and heat distribution, ensuring that every peanut is evenly roasted to perfection. With features like high heat resistance, superior durability, and compatibility with various roasting equipment, these belts not only optimize energy use but also elevate roasting consistency and quality. Whether for small-scale operations or high-capacity industrial systems, wire mesh roasting belts are setting new benchmarks for efficiency and sustainability in peanut processing.

Understanding Wire Mesh Roasting Belts

What Are Wire Mesh Roasting Belts?

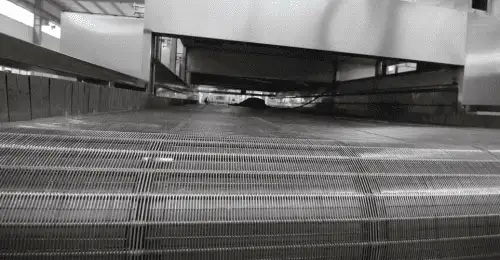

Wire mesh roasting belts are specialized conveyor systems designed to meet the demands of modern peanut roasting machines. Their open-weave structure allows for superior heat and airflow circulation, ensuring that every peanut is evenly roasted while minimizing energy waste. These belts are essential in achieving the perfect balance of roasting consistency, flavor enhancement, and efficiency, making them indispensable in both small-scale and industrial roasting operations.

Materials and Construction of Durable Roasting Belts with Food-Grade Materials

Crafted from premium stainless steel, wire mesh roasting belts are built to withstand the high temperatures and rigorous conditions of nut processing. The use of food-grade materials ensures that the belts meet strict hygiene and safety standards, making them ideal for industrial food processing environments. These belts are designed with precision, featuring robust construction that resists warping and maintains structural integrity even after prolonged use.

Key Features: Heat Resistance, Flexibility, and Belt Compatibility with Various Nut Roasting Equipment

Wire mesh roasting belts boast exceptional heat resistance, allowing them to perform efficiently at temperatures ranging from low to extreme heat settings. Their flexibility ensures smooth operation, adapting seamlessly to different types of roasting equipment, including drum roasters, conveyor roasters, and continuous roasting systems. Additionally, their compatibility with various nut roasting equipment, such as peanut roasting machines and multi-purpose nut processing lines, makes them a versatile and cost-effective solution for any roasting setup.

How Wire Mesh Belts Function in Peanut Roasting Machines

The Role of Wire Mesh Roasting Belts in Airflow Control and Heat Distribution

Wire mesh roasting belts are designed to optimize airflow control and heat distribution within peanut roasting machines. Their open-weave structure ensures that hot air circulates evenly across the roasting chamber, eliminating cold spots and ensuring consistent roasting quality. This precision airflow not only enhances the flavor profile of the peanuts but also reduces roasting time, making the entire process more efficient.

Differences Between Wire Mesh Belts and Other Systems in Batch Roasters or Continuous Roasters

Compared to traditional flat belts or solid conveyor systems, wire mesh belts provide unparalleled advantages in continuous roasters. They maintain a steady flow of peanuts while supporting high-capacity operations, making them ideal for industrial-scale production. Their lightweight and durable construction reduces wear and tear, ensuring a longer lifespan and lower maintenance costs.

These features make wire mesh roasting belts a cornerstone of modern peanut processing. They blend efficiency with superior performance to meet the demands of today’s roasting industry.

The Energy Efficiency Advantage

How Wire Mesh Belts Optimize Heat Transfer

Wire mesh roasting belts are engineered to maximize heat transfer during the peanut roasting process. Their open-weave design allows for efficient heat penetration and retention, ensuring that every peanut receives consistent exposure to the roasting temperature. This optimized heat transfer reduces energy waste and speeds up the roasting cycle, making the process both time and cost-efficient.

Minimizing Energy Loss with Optimized Airflow in Peanut Roasting Machines

One of the standout features of wire mesh roasting belts is their ability to minimize energy loss through superior airflow control. By allowing hot air to circulate freely, these belts maintain consistent temperatures across the roasting chamber, reducing the need for excessive energy input. This makes them an integral component of energy-efficient peanut roasting machines, ideal for both small-scale and industrial peanut roasting setups.

Reducing Energy Costs with Wire Mesh Roasting Belts

Wire mesh belts deliver real-world savings by cutting down on energy consumption while maintaining high-quality roasting standards. For commercial peanut roasters and small-scale operators alike, the reduced energy costs translate into significant long-term financial benefits. Additionally, their compatibility with eco-friendly roasters supports sustainable roasting practices, helping businesses meet environmental goals without compromising performance.

Enhancing Roasting Quality

Uniform Roasting Through Superior Airflow Control

Wire mesh roasting belts play a pivotal role in achieving uniform roasting, thanks to their ability to enhance airflow control. The open-weave structure ensures that hot air evenly envelops each peanut, eliminating inconsistencies in roasting. This results in peanuts with consistent color, texture, and flavor—a critical requirement for maintaining high product standards in commercial and industrial peanut roasting.

The Impact of Heat and Temperature Control on the Peanut Flavor Profile

Precision temperature control is essential for unlocking the full flavor potential of peanuts. Wire mesh roasting belts enable precise heat management, allowing operators to fine-tune roasting temperatures and durations. This control not only enhances the natural nutty aroma and sweetness of peanuts but also ensures that the final product meets consumer expectations for crispness and flavor.

How Wire Mesh Belts Improve Roasting Cycle Efficiency

Efficiency is key in high-volume peanut roasting operations, and wire mesh belts deliver on this front. By facilitating faster heat transfer and consistent roasting, these belts significantly reduce roasting cycle times. Their ability to handle high-capacity loads without compromising quality makes them indispensable for meeting the demands of industrial-scale production, where efficiency and quality go hand in hand.

Practical Benefits for Commercial Peanut Roasters

Maintenance and Longevity of Wire Mesh Roasting Belts

Wire mesh roasting belts are designed with durability in mind, ensuring they withstand the rigors of high-temperature and continuous operations. Their sturdy construction minimizes wear and tear, extending their lifespan significantly. Additionally, these belts are easy to clean and maintain, reducing downtime for maintenance and ensuring uninterrupted production cycles. Regular cleaning and proper handling can further enhance their longevity, making them a cost-effective investment for commercial peanut roasters.

Compatibility with Various Peanut Roasting Machines

One of the greatest advantages of wire mesh roasting belts is their adaptability to a wide range of roasting equipment. From drum roasters to conveyor roasters, these belts seamlessly integrate into different systems, ensuring optimal performance across various setups. Their compatibility with both small-scale peanut roasters and large industrial roasting machines makes them versatile enough to meet the diverse needs of peanut processing businesses.

Wire mesh roasting belts not only streamline roasting operations but also provide the flexibility required to adapt to evolving production demands, making them an invaluable asset for commercial peanut roasting.

Designing for Versatility

Customization Options for Wire Mesh Roasting Belts

Wire mesh roasting belts are not one-size-fits-all solutions—they can be tailored to meet specific production requirements. Manufacturers offer customized belts to fit varying roaster capacities, ensuring optimal performance regardless of machine size. From adjusting the mesh density to selecting specific materials for enhanced durability, these customization options allow peanut processors to maximize efficiency while catering to their unique operational needs.

Specific Adjustments for Different Nut Processing Lines

Beyond peanuts, wire mesh roasting belts are ideal for other nut processing lines, including almonds, cashews, and hazelnuts. Adjustments such as mesh opening sizes and belt width ensure compatibility with diverse products, making them versatile tools in multi-product processing facilities. These tailored configurations enable smooth transitions between products, reducing downtime and boosting overall production efficiency.

Supporting Other Nut Roasting Applications

Wire mesh roasting belts aren’t limited to peanut roasting—they excel in supporting broader nut roasting applications. Whether used in continuous roasting systems or batch processes, these belts deliver consistent results across various nuts. Their adaptability ensures high-quality roasting for a range of products, making them indispensable in modern nut processing lines.

Meeting Industry Standards

Ensuring Food Safety with Wire Mesh Roasting Belts

Wire mesh roasting belts are crafted from food-grade materials, ensuring compliance with the stringent hygiene standards required in industrial food processing. These materials prevent contamination during the roasting process, guaranteeing that the final product meets food safety regulations. Their easy-to-clean design further enhances hygiene, reducing the risk of bacterial buildup and ensuring a clean production environment.

Compliance with Established Peanut Roasting Standards

Modern peanut roasting facilities operate under strict industry standards, and wire mesh roasting belts are engineered to meet these requirements. Their durable construction and consistent performance align with the expectations of industrial peanut roasters, ensuring reliability and quality at every stage of production. By adhering to these standards, wire mesh belts help businesses maintain certifications and build consumer trust.

Addressing Eco-Friendly Concerns in Nut Roasting

Sustainability is an increasingly important consideration in the food industry, and wire mesh roasting belts contribute to eco-friendly practices. Their optimized airflow and heat retention reduce energy consumption, making roasting processes more energy-efficient. This aligns with the goals of businesses looking to lower their environmental footprint while maintaining high production standards. Combined with the use of energy-efficient roasters, wire mesh belts support a greener, more sustainable approach to nut processing.

Conclusion

Why Wire Mesh Roasting Belts Are a Must-Have for Any Advanced Roasting Equipment

Wire mesh roasting belts have proven to be essential components in modern peanut roasting operations. Their ability to optimize airflow, ensure even heat distribution, and reduce energy consumption makes them indispensable for advanced roasting equipment. Whether in small-scale roasters or industrial systems, these belts deliver superior performance, enhancing roasting quality while keeping costs and energy use under control.

Combining Peanut Production Efficiency, Cost-Effective Roasting, and Superior Quality

By integrating wire mesh roasting belts into their operations, peanut processors can achieve a perfect balance of efficiency, sustainability, and product excellence. These belts streamline production, maintain high standards of food safety, and reduce operational costs. For businesses looking to stay competitive in the peanut processing industry, wire mesh roasting belts offer a game-changing solution that combines quality, eco-friendliness, and cost-effectiveness.

Wire mesh roasting belts are not just a tool—they are a critical innovation driving the future of peanut roasting. They help businesses meet growing demands while prioritizing efficiency and sustainability.