Problem: It is easy to underestimate the impact of processing equipment on your final product. For commercial producers, manual grinding or relying on standard kitchen blenders creates a massive bottleneck. You struggle with inconsistent textures, overheating motors, and the inability to keep up with orders, leaving you stuck in a cycle of low output and high frustration.

Agitate: Imagine this: You have a bulk order due, but your current equipment jams halfway through. 30 seconds too long, and the batch is scorched, ruining the flavor profile you worked so hard to perfect. Is your current process costing you customers? The risk of variable texture and machine burnout isn’t just an operational headache; it is a direct hit to your profit margins.

Solution: Here’s the deal: The industrial Peanut Butter Grinder Machine is the bridge between amateur production and professional scalability. By utilizing high-speed friction technology, these machines ensure uniform emulsion and continuous output, solving your consistency problems instantly. This guide covers the top benefits of upgrading your line.

1. How Does a Peanut Butter Grinder Machine Improve Taste?

Direct Answer: A commercial Peanut Butter Grinder Machine utilizes precision-engineered grinding stones or discs to create a uniform particle size that standard blenders simply cannot achieve. This specific mechanical action unlocks the full flavor profile of the nut by releasing oils immediately without generating flavor-damaging heat pockets. You might be wondering how this differs from a high-powered blender. The secret lies in the gap adjustment, allowing for a precise emulsion that coats the palate perfectly.

Achieving Ultra-Smooth Textures

When you utilize professional peanut grinder technology, the difference in mouthfeel is immediate. Precision discs pulverize nuts to micron-level fineness, eliminating the “gritty” texture common in lower-grade processing. This smoothness allows the peanut flavor to spread evenly across the tongue, intensifying the taste experience for the consumer. Unlike chopping blades that leave irregular chunks, grinding stones create a cohesive paste that feels luxurious.

Why is Oil Retention Crucial?

But wait, there’s more… Retaining natural oils is vital for authentic flavor. In high-speed blenders, air is often whipped into the mix, which can oxidize oils and dull the taste. A dedicated grinder uses friction and pressure to press the oils out of the nut cell structure instantly. This natural oil acts as a flavor carrier, delivering the robust, roasted notes of the peanut without the need for added hydrogenated stabilizers or artificial flavor enhancers.

Better Taste or Just Better Texture?

Ideally, you want both because they are intrinsically linked. Texture influences how the human palate perceives flavor; a smoother grind allows for faster flavor release. When the particle size is inconsistent, the brain focuses on chewing rather than tasting. By ensuring a silky consistency, the grinder allows the rich, nutty notes to take center stage immediately upon consumption.

Key Takeaway: Precision grinding releases natural oils instantly, enhancing flavor without additives.

2. Why Install a Peanut Butter Grinder Machine for Efficiency?

Direct Answer: Commercial units are designed to operate continuously, processing hundreds of kilograms per hour compared to the small, intermittent batches required by kitchen appliances. By automating the feed and grind cycle, a peanut butter grinder machine transforms your workflow from a stop-and-go struggle into a seamless stream of product. It gets better: the reduction in downtime means your yield per shift skyrockets.

Continuous vs. Batch Processing

The primary advantage of industrial equipment is the duty cycle. Standard appliances require frequent pauses to cool down the motor or scrape down the sides of the bowl. A commercial grinder, integrated into a production line efficiency strategy, features hoppers that allow for continuous raw material feeding. You simply pour roasted nuts in the top, and finished butter flows from the bottom, non-stop, hour after hour.

Reducing Labor Hours

Think about it: relying on manual methods is a massive drain on human resources. One operator managing a single high-capacity grinder can do the work of five manual laborers attempting to produce the same volume with smaller tools. This frees up your staff to focus on high-value tasks such as packaging, quality control, or logistics, rather than standing over a machine hitting a “pulse” button.

Speeding Up Order Fulfillment

Meeting bulk B2B orders requires predictability. If a client orders 500kg of peanut butter, you cannot rely on equipment that might overheat after 20kg. Consistent output rates allow for accurate production planning. You know exactly how many hours a job will take, allowing you to promise delivery dates with confidence and meet tight deadlines without paying for staff overtime.

Key Takeaway: A commercial grinder transforms production from a bottleneck into a streamlined flow.

3. How Does a Peanut Butter Grinder Machine Preserve Nutrients?

Direct Answer: Advanced grinding technology employs low-temperature milling methods to prevent the overheating of nuts, which is critical because high heat destroys heat-sensitive vitamins and oxidizes healthy fats. By maintaining a lower processing temperature, the Peanut Butter Grinder Machine ensures that the nutritional integrity of the peanut—specifically Vitamin E and protein structures—remains intact.

The Danger of Overheating Peanuts

Friction generates heat, and in poorly designed machines, this heat can spike rapidly. If the temperature exceeds critical thresholds during grinding, the natural oils in the peanuts can begin to burn or degrade. This not only affects the flavor, producing a bitter aftertaste, but it also destroys heat-sensitive nutrients. Industrial grinders utilize cooling systems or specific stone geometries to dissipate heat effectively during the milling process.

Retaining Vitamin E and Healthy Fats

Here is the kicker: peanuts are prized for their high Vitamin E content and monounsaturated fats. Cold milling technologies keep processing temperatures stable, preserving these antioxidant properties. When you protect the fats from heat-induced oxidation, you also prevent the formation of free radicals, ensuring the final product delivers the health benefits consumers expect from a natural nut butter.

Producing a Healthier End Product

Today’s market demands “clean label” products. By using a machine that preserves nutrients mechanically, you reduce the need for chemical preservatives that are often used to mask oxidation or shelf-life issues. A nutrient-dense, naturally processed peanut butter appeals to health-conscious consumers and allows you to market your product as a premium, wholesome food source.

Key Takeaway: Low-heat mechanics ensure your product remains nutritious and shelf-stable.

4. Why Is a Peanut Butter Grinder Machine a Cost-Effective Asset?

Direct Answer: While the upfront investment is higher than consumer equipment, the ROI is realized rapidly through lower labor costs, significantly reduced waste, and the strategic ability to buy raw nuts in bulk rather than expensive pre-made paste. Owning your processing equipment insulates you from supplier price hikes on finished pastes. What’s the catch? There isn’t one—it is simply a matter of economies of scale.

Lowering Raw Material Costs

Purchasing pre-ground peanut paste commands a premium price because you are paying the supplier for their labor, energy, and equipment wear. By bringing the grinding process in-house, you can purchase raw or roasted nuts in bulk tonnage. The price difference between whole nuts and finished paste is substantial, often allowing the machine to pay for itself within the first year of operation based on material savings alone.

Long-Term Equipment Durability

Industrial motors are built for the long haul. A cheap blender might cost less initially, but if you have to replace it every three months due to burnout, the costs add up quickly. A commercial grinder is a capital asset designed to last for years, not months. The reduced frequency of replacement and repair translates to a lower total cost of ownership over the lifespan of the business.

Is It Cheaper to Buy or Make?

When you control the production, you control the inventory. You no longer need to store expensive barrels of paste that might spoil; you can grind on demand. This “Just-in-Time” production capability reduces spoilage costs and storage fees. Furthermore, capturing the manufacturing margin that used to go to your suppliers significantly widens your profit margin per jar sold.

Key Takeaway: In-house grinding significantly widens profit margins per jar.

5. What Else Can You Process With a Peanut Butter Grinder Machine?

Direct Answer: These machines are versatile powerhouses capable of processing not just peanuts, but also almonds, cashews, sesame seeds for tahini, cocoa nibs, and even chili pastes. This flexibility allows businesses to pivot quickly to market trends without purchasing separate machinery for every new product line. The Peanut Butter Grinder Machine is truly a multi-functional asset.

Making Almond and Cashew Butter

Almonds and cashews are harder than peanuts and require robust motors to process effectively. The high-torque engines found in commercial grinders handle these dense nuts without stalling. This capability allows you to enter the lucrative market of “alternative” nut butters, which often command higher retail prices than standard peanut butter.

Processing Sesame for Tahini

You might be surprised: the same machine that grinds peanuts can produce ultra-fine tahini. Sesame seeds require an exact grind to achieve the necessary liquid consistency for high-quality tahini. By adjusting the grinding head, you can switch from peanut butter production in the morning to tahini production in the afternoon, maximizing the utility of your nut processing capabilities.

Expanding Your Product Catalog

Versatility is a safety net for your business. If the price of peanuts spikes, you can easily shift production to sunflower seed butter or pumpkin seed paste. This adaptability allows you to launch seasonal blends or test small batches of new products without significant capital expenditure. You are not just buying a peanut grinder; you are buying a food processing platform.

Key Takeaway: One machine can launch multiple product lines, maximizing equipment utility.

6. Why Is a Sanitary Peanut Butter Grinder Machine Vital for Safety

Direct Answer: Constructed with food-grade stainless steel (usually 304 or 316), these machines naturally resist corrosion and prevent the bacterial harborages that are common in plastic or composite components. In the food industry, hygiene is not just a requirement; it is your brand’s reputation on the line. Let’s face it: you cannot afford a recall.

The Importance of Stainless Steel

Stainless steel is the gold standard in food safety for a reason. It is non-porous, meaning bacteria, oils, and allergens cannot seep into the material itself. It is also resistant to the acidic cleaning agents and high temperatures used during sanitation cycles. Unlike plastic hoppers that can scratch and trap pathogens, stainless steel remains smooth and hygienic after years of rigorous use.

Easy Disassembly for Cleaning

If a machine is difficult to clean, it won’t get cleaned properly—that is a fact of human nature. Industrial designers prioritize “Clean-in-Place” (CIP) systems or easy tool-free disassembly. This ensures that your staff can thoroughly sanitize the grinding mechanism between batches, preventing cross-contamination (e.g., preventing peanut residue in an almond butter batch) and ensuring compliance with allergen control protocols.

Meeting Food Safety Standards

Commercial grinders are built to comply with strict regulations from bodies like the FDA, GMP, and ISO. Operating with compliant machinery simplifies your health inspections and audits. It demonstrates to your customers and regulators that you take food safety seriously, which is essential for securing contracts with major retailers or distributors.

Key Takeaway: Stainless steel construction is non-negotiable for commercial food safety compliance.

7. How Does a Peanut Butter Grinder Machine Allow Custom Textures?

Direct Answer: Adjustable grinding heads allow operators to switch between ultra-smooth, creamy, and crunchy textures in seconds without the complex process of changing parts. This granular control means you can cater to specific client requests or consumer preferences instantly. The Peanut Butter Grinder Machine puts the control in your hands.

Adjusting Grinding Fineness

The core of the machine involves a stator and rotor with an adjustable gap between them. By turning a dial, you can change this gap by micrometers. A tighter gap produces a silky, liquid-smooth paste ideal for industrial fillings or smoothies. A wider gap results in a coarser, thicker rustic butter. This precision allows you to dial in the exact “mouthfeel” your target demographic prefers.

Crunchy vs. Creamy Markets

Here is the truth: the market is split, and you need to serve both sides. While creamy is the standard, there is a dedicated and loyal market for crunchy textures. Commercial lines often integrate a mixing phase where chopped nuts are added back into a smooth base, or the grinder is set to a coarse setting to create a textured product in a single pass.

Creating Signature Blends

Customization is how you differentiate your brand from the generic store brands. Perhaps you want a “super-chunk” variety or a “whipped” texture. The flexibility of a commercial grinder allows you to experiment and develop customized solutions and signature blends that define your brand identity and keep customers coming back for that unique experience they can’t get elsewhere.

Key Takeaway: Flexibility in texture settings allows you to cater to diverse customer preferences instantly.

8. Why Does a Peanut Butter Grinder Machine Ensure Batch Consistency?

Direct Answer: Automated feed systems and consistent motor speeds remove human error from the equation, ensuring that every jar tastes and feels exactly the same as the last. When a customer buys your product, they expect the same experience every time; this machine guarantees that reliability. Here is why this matters: inconsistency kills brand loyalty.

Eliminating Human Error

Manual processing is subject to the operator’s fatigue, attention span, and technique. One batch might be ground for 5 minutes, the next for 7. These small variances lead to noticeable differences in the final product. A machine does not get tired. It applies the exact same shear force and rotational speed to every single peanut, ensuring the 1,000th jar is identical to the first.

Standardizing Product Output

With a machine, your recipes become repeatable formulas rather than guesses. You can document the specific settings—flow rate, gap size, motor speed—and replicate the product perfectly even if a different staff member is running the shift. This standardization is critical when you are trying to scale your business and secure distribution deals where product uniformity is contractually required.

Building Brand Reliability

Consistency builds trust. If a customer opens a jar and finds oil separation one month and a dry block of paste the next, they will switch brands. Reliable machinery ensures that your product delivers on its promise every time. This reliability protects your brand reputation and reduces the costs associated with returned products or customer complaints due to “off” batches.

Key Takeaway: Reliable machinery guarantees that the customer’s second purchase is as good as their first.

9. How Easy Is It to Operate a Commercial Peanut Butter Grinder Machine

Direct Answer: Modern units are designed with “Plug and Play” simplicity in mind, requiring minimal training for staff to operate safely and effectively. Complex engineering is hidden behind user-friendly interfaces, meaning your production doesn’t stop just because your head technician is on vacation. The modern Peanut Butter Grinder Machine prioritizes usability.

Simplified Control Panels

Gone are the days of confusing levers and gauges. Modern grinders feature intuitive control panels, often with digital displays that show motor load, temperature, and speed. Simple “Start,” “Stop,” and “Emergency Stop” buttons make operation straightforward. This simplicity reduces the cognitive load on operators, allowing them to focus on maintaining a steady material feed and monitoring output quality.

Minimal Training Requirements

Think about this: high staff turnover is a reality in manufacturing. If your equipment requires a PhD to operate, you are vulnerable. Commercial grinders are designed so that a new staff member can be trained on basic operation and safety protocols in hours, not weeks. Safety guards and sensors are integrated to prevent common operator errors, protecting both your staff and the machine.

Routine Maintenance Made Easy

Maintenance is key to longevity, and manufacturers know this. Good designs feature accessible grease points and clear maintenance schedules. Many machines are designed with tool-free access to the grinding chamber, making daily cleaning and inspection a quick task rather than a dreaded chore. This ease of maintenance ensures that it actually gets done, preventing long-term mechanical issues.

Key Takeaway: Advanced technology doesn’t mean complex operation; modern designs prioritize user-friendliness.

10. How Do You Choose the Right Peanut Butter Grinder Machine Model?

Direct Answer: Selection depends heavily on your specific capacity needs (kg/hr), motor power, material quality, and the availability of after-sales support from the manufacturer. It is not just about buying a machine; it is about partnering with a supplier who understands your production goals.

Assessing Your Production Volume

The first step is realistic forecasting. Don’t just buy for today’s volume; buy for where you want to be in two years. If you currently need 50kg/hr, consider a machine capable of 100kg/hr to accommodate growth without needing an immediate upgrade. Also, consider the hardness of the nuts you plan to grind—harder nuts may require a model with higher horsepower and torque.

Checking Manufacturer Warranties

Ready for the good part? Reputable suppliers stand behind their equipment. Look for manufacturers that offer solid warranties on motors and core components. Check the availability of consumables like grinding discs or stones. A cheap machine becomes very expensive if you have to wait six weeks for a replacement part to ship from overseas while your production line sits idle.

Why After-Sales Support Matters

A machine is an investment relationship. You need a partner who can offer technical support, whether that’s troubleshooting an issue remotely or sending a technician for installation. Consult our experts to understand the level of support available. Good support ensures that your investment continues to generate revenue for decades.

Key Takeaway: Partner with a manufacturer that offers technical upgrades and robust support.

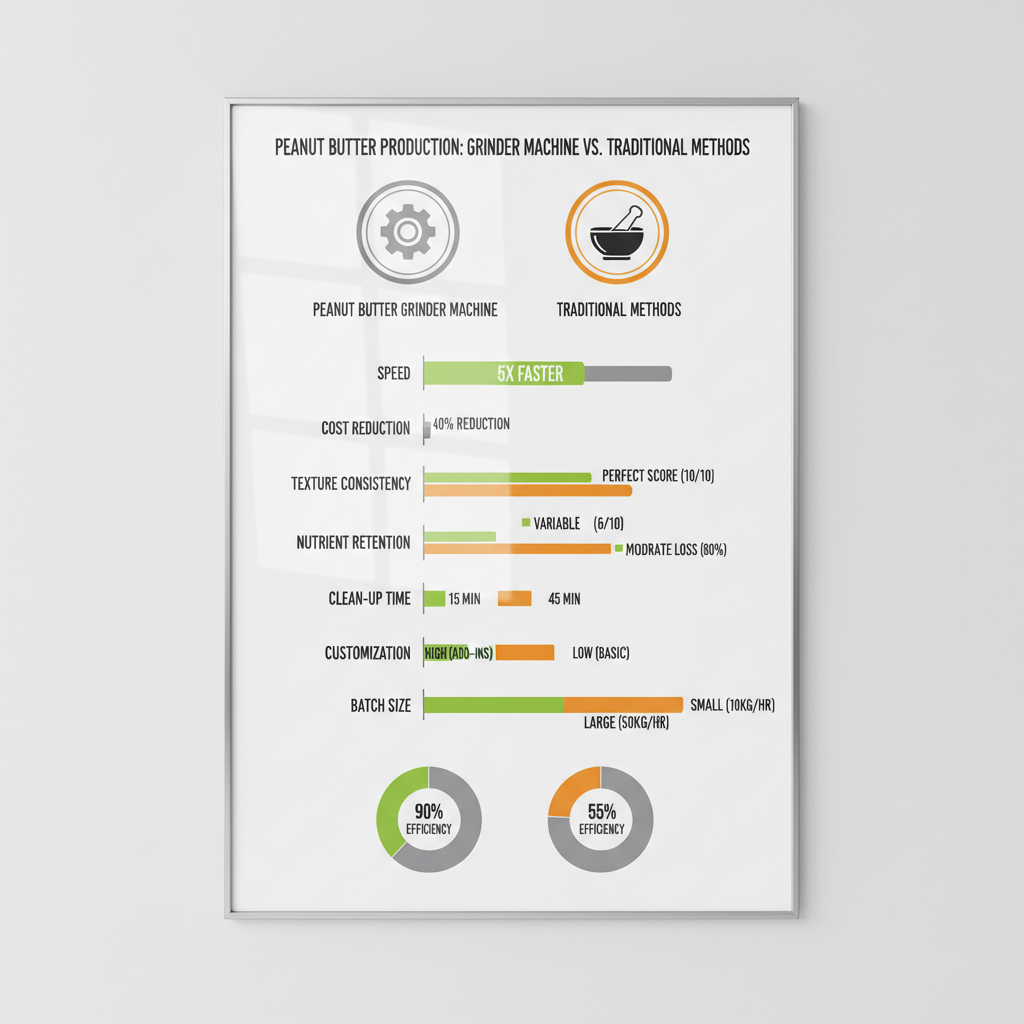

Comparison of Production Methods

| Feature | Manual/Blender Method | Commercial Grinder Machine |

|---|---|---|

| Output | Low (<10kg/hr) | High (50kg – 1000kg+/hr) |

| Consistency | Variable | Precise & Uniform |

| Durability | Prone to overheating | Industrial continuous duty |

| Versatility | Limited | Multi-nut capability |

| Hygiene | Difficult to sanitize | Food-grade Stainless Steel |

Conclusion

Summary: We have explored how the right equipment can revolutionize your business. From unlocking superior flavor profiles through precision milling to ensuring rigorous food safety standards with stainless steel construction, the benefits are clear. You gain efficiency, cut raw material costs, and deliver the consistent quality your customers crave.

Final Thought: The transition to a professional Peanut Butter Grinder Machine isn’t just an upgrade; it is a business necessity for growth. You cannot scale a brand on inconsistent manual processes. To compete in today’s market, your infrastructure must match your ambition.

Call to Action: Ready to scale your production? Contact Us today to find the perfect grinder for your facility and start producing the world-class peanut butter your brand deserves.

FAQ

Q1: Can a peanut butter grinder machine process wet peanuts?

No, peanuts must be roasted and cooled before grinding. Wet or raw peanuts contain high moisture levels which can clog the grinding discs, creating a gummy paste rather than a smooth butter, and potentially damaging the machine.

Q2: How do I clean a commercial peanut butter grinder?

Most machines utilize a “Clean-in-Place” method where you circulate hot water and food-safe cleaning solution through the hopper. This is followed by a simple disassembly to deep clean the grinding stones or discs and the stator to remove any residual oils.

Q3: Does the machine require added oil to make butter?

High-quality commercial machines use high-speed friction and pressure to release the nut’s natural oils effectively. Therefore, you typically do not need to add extra oil unless a specific recipe calls for it or you are processing a nut variety with very low natural oil content.

Q4: What is the lifespan of the grinding stones?

With proper maintenance and regular use, high-grade stainless steel grinding stones or discs are designed to be durable. They can last for several years before needing replacement, although this depends on the volume processed and the hardness of the nuts.

Q5: Can this machine handle chocolate or cocoa nibs?

Yes, many industrial grinders are versatile enough to process cocoa nibs into liquor or paste. They can also grind sesame seeds, almonds, and cashews, making them a multi-purpose asset for any food production facility.