Nut Dicing Machine

Precision-Cut Nut Dicing: Clean, Consistent, and Continuous Operation.

Stainless Steel Construction Ensures Food-Grade Hygiene and Durability

Nut Dicing Machine

Good Helper for Food Production

The Nut Dicing Machine is designed to create cubes from whole or split nuts, whether peeled or with hulls. It features interchangeable rollers, enabling the production of various cube sizes and measurements, catering to different product specifications. To ensure a consistent final product, it is recommended to pair the Nut Dicing Machine with a sieving machine at the outlet. This additional step effectively separates different-sized chopped nuts pieces, resulting in a uniform specification of nut cubes. The Nut Dicing Machine is essential for producing precisely diced nuts with consistent quality across various nut processing applications.

Application:

peanuts

Almond

Hazelnut

Pistachio

Cashew nuts

Walnut

Macadamia Nut

Pecan

Overview

The Nut Dicing Machine (also known as Nut Dicer or Peanut Cutting Machine) is an advanced piece of equipment designed to chop various nuts, including peanuts, almonds, walnuts, hazelnuts, and more, into precise, uniform sizes. This machine is essential for food processing industries, especially in the production of ingredients for doughnuts, ice creams, baked goods, salads, and confectioneries.

Equipment Components

1. Raw Material Hopper

The starting point of the dicing process, the raw material hopper is where nuts such as peanuts, almonds, or other granular materials are initially loaded. This hopper is designed to hold and gradually release the nuts into the processing line, ensuring a continuous and steady feed.

2. Vertical Elevator & Z Bucket Elevator

These components are responsible for vertically lifting the nuts from the hopper to the processing section of the machine. The Z bucket elevator, specifically, allows for smooth and gentle transportation of the nuts, minimizing breakage and ensuring that the nuts are evenly distributed as they move towards the cutting section.

3. Electromagnetic Vibration Feeder

This feeder ensures that the nuts are evenly spread and fed into the cutting section at a consistent rate. The electromagnetic vibration provides precise control over the flow of the nuts, reducing the likelihood of clogging and ensuring uniform feeding, which is crucial for consistent chopping results.

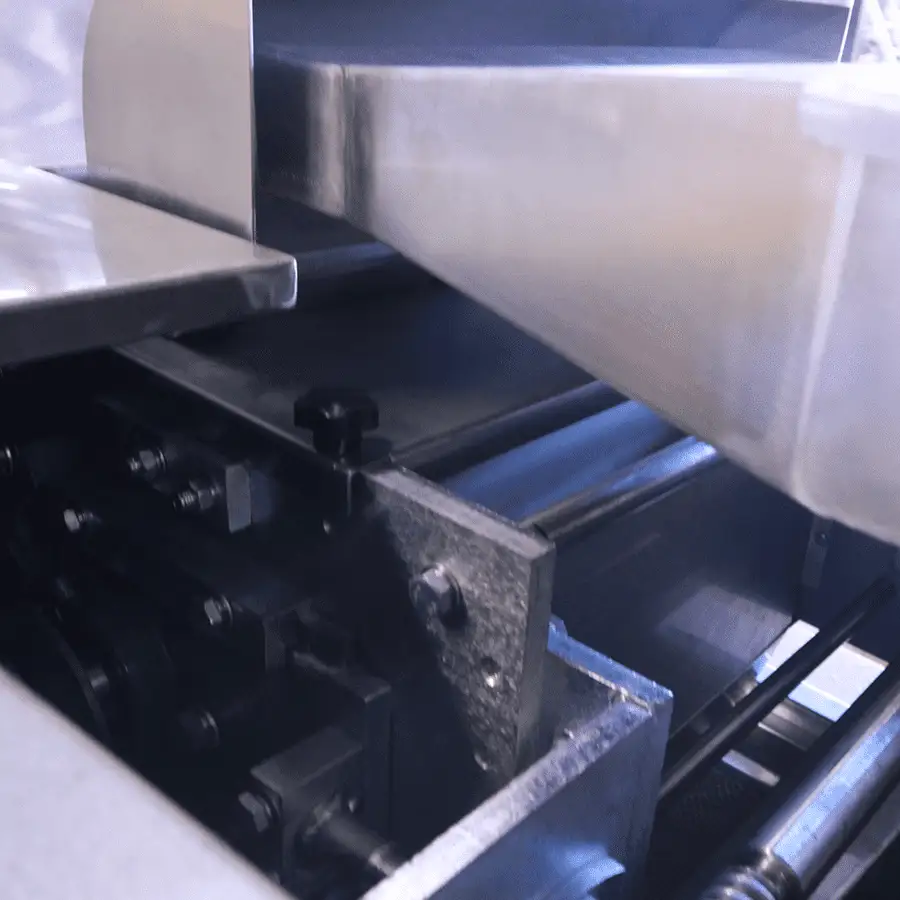

4. 1st Cutter

The first cutter is responsible for the initial chopping of the nuts. This stage typically reduces the nuts into coarse pieces, setting the stage for further refinement in the subsequent cutting phase. The cutter is designed with durable, sharp blades that can handle various nut types without compromising efficiency.

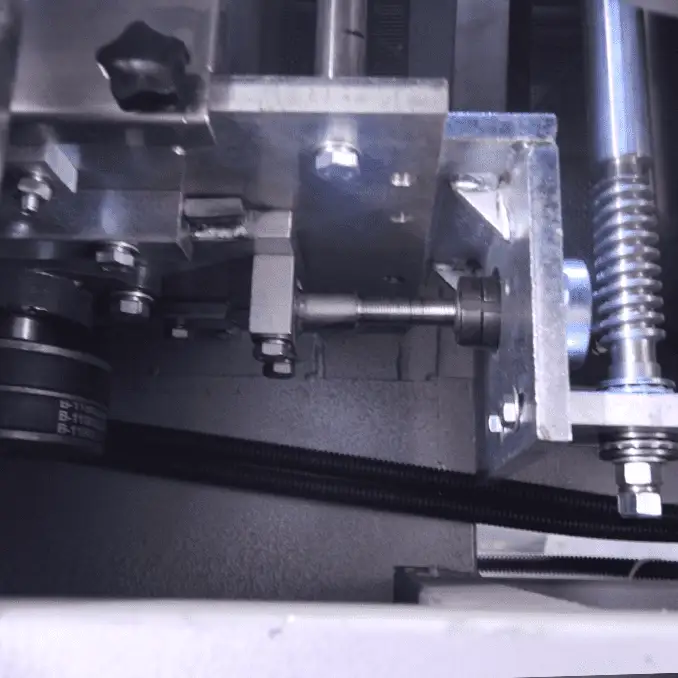

5. 2nd Cutter

After the initial chopping, the nuts are passed to the second cutter. This cutter further refines the pieces, achieving the desired size and uniformity. The second cutter works in tandem with the first to ensure that all nuts are chopped to the precise specifications required for the final product.

6. Vibration Sifter

Following the cutting process, the vibration sifter plays a crucial role in sorting and grading the chopped nuts. It uses vibratory motion to separate the pieces based on size, ensuring that only uniformly chopped nuts proceed to the collection stage. This component is essential for maintaining product quality and consistency. Our sifter design is 2 sets, 5 outlets.

7. Transmission Mechanism

The transmission mechanism is the core system that drives the operation of the cutters and sifters. It ensures that all moving parts work in harmony, allowing the machine to function efficiently and reliably over extended periods.

8. Finished Chopped Peanut Collector

Once the nuts have been chopped and sifted, they are collected by different outlets separately, this component ensures that the final product is securely stored before it is moved on to the packaging or further processing stages.

9. Electrical Control Cabinet

The electrical control cabinet houses all the controls and settings for the Nut Dicing Machine. It allows operators to adjust the speed, cutting size, and other parameters, ensuring that the machine can be tailored to specific processing requirements. The control cabinet is equipped on beginning side of nut dicer, with safety features to protect both the equipment and the operators.

Key Functions

Versatile Chopping: The Nut Dicing Machine is capable of chopping a wide variety of nuts and granular materials into different sizes. It operates efficiently on split blanched peanuts, producing uniform pieces that are ideal for various foods applications.

Two-Stage Dicing Process: The machine features a dual-stage chopping process. Initially, peanuts are fed into the machine via a vertical conveyor (or Z bucket elevator) and chopped into coarse grains by the first cutter device. Passing through a wire mesh screen, larger chopped pieces move forward to the second stage for chopping. The result is a consistent final product with varying sizes tailored to specific needs.

Vibration Sifting and Sorting: The Nut Dicer is equipped with a vibrating sifter that sorts chopped nuts into four uniform specifications (above 5mm, 3-5mm, 2-3mm, and 1-2mm), with any particles below 1mm classified as powder. This ensures that each batch meets precise size requirements.

Features

High Degree of Automation: The Nut Dicing Machine operates with a high level of automation, minimizing the need for manual intervention and ensuring consistent output.

Uniform Chopping: The machine is designed to produce uniform nut pieces with minimal variance, which is crucial for maintaining product quality in food processing.

No Oil Leak: The cutting devices are special structure, which is machined by precision CNC machine, all types of nuts are cut fast when touching the rotation cutter. Such nut dicer’s design prevents oil leakage cause loss on nut materials.

Low Noise Operation: Built with noise reduction in mind, the Nut Dicer operates quietly, contributing to a more pleasant working environment.

Advantages

High Output and Efficiency: The Nut Dicing Machine is designed for high efficiency, delivering a large output with minimal energy consumption. This makes it an ideal choice for large-scale food production facilities.

Precise Particle Size: The machine ensures uniform particle size, which is essential for consistency in product quality. The cutting device can be customized size to meet various processing requirements.

Low Material Waste: The machine is engineered to minimize material consumption and waste, reducing costs and improving overall efficiency.

Reliable and Durable: Constructed from high-quality materials like SUS304 stainless steel, the Nut Dicer is built to last, ensuring long-term reliability and consistent performance in demanding production environments.

Technical Parameter

Capacity 500kg/hr

Rated voltage: 380V/50HZ/3-phases

Power: 4.75kw

Outer dimension: 4560×3000×2886mm(L×W×H)

Weight:950kg

Nut Dicer Gallery

Precision Cutting, Sharp Edge Chopped Cubes

The peanut chopping process is basically technology for food production, particular diced nuts make you distinguished from others.

Frequently Asked Question

Welcome to ask more questions about nuts chopping process, full communication help you learn more about our nut dicing machine.

Does raw material need to be graded or not? Are they blanched or not?

Grading isn’t necessary, the blanched process depends on the material type

What’s the proper moisture content of the material for chopping?

Below 4~5%, too much humidity will cause a block on the rolling cutter device

Is the shaft rotation speed adjustable?

The nut dicer speed is fixed

How is an interval between the shafts being adjusted? Are there any indicators or signs?

The cutters are divided into fixed/adjustable cutters. When the cutter gap needs to be adjusted, only rotate the hand wheel which is installed outside of the chopper, then the mechanic structure will move the adjustable cutter’s position, and then reduce or enlarge the distance between two cutters. Meanwhile, we put a reader on the hand wheel to mark the position of the adjustable cutting device.

Are the screens on the vibrating sifters quick-detachable?

No, they are welded wire mesh and fixed

Are the shafts available for maintenance, e.g. Washing and cleaning?

Cutter device can be disassembled from the machine for the entire hygiene cleaning because it is made of stainless steel.

Customized

Solutions

We tailor equipment to meet specific processing requirements.

Convenient Maintenance

Simple maintenance guidance for stable equipment performance.

Professional

Installation

Comprehensive installation to ensure efficient operation.

Timely Support

We provide prompt technical assistance with 24/7 support.

You Also May Like

Related Equipment

Let Us Know, Whaterver You Need

Dont Heistate To Ask Question

Enhance your production with our Nut Dicing Machine—contact us today for a quote and customized solutions!