Project

We provide industry-leading equipment

High-quality components ensure optimal performance with minimal maintenance required.

Our Projects

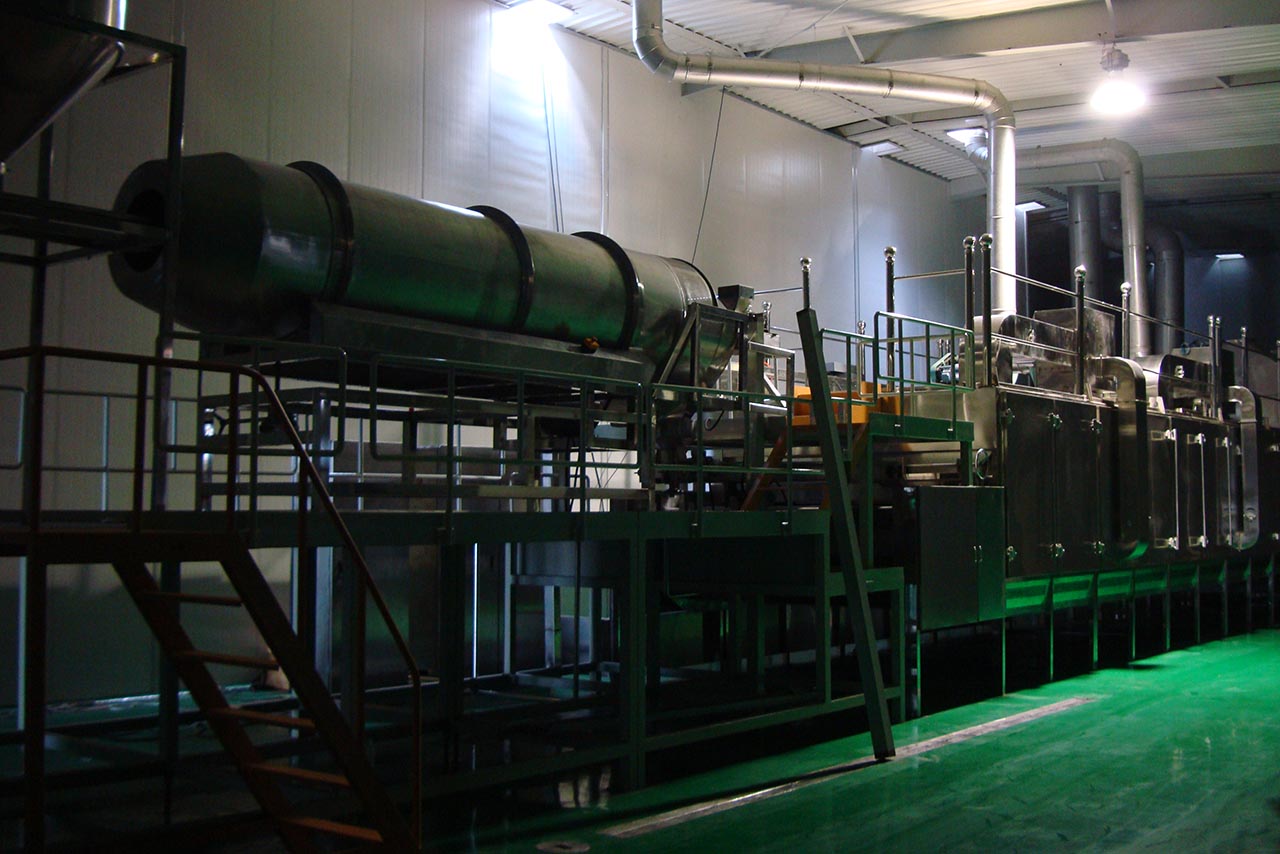

Golden Machinery project solution focuses on providing super-quality roasting results for peanut manufacturers. With a commitment to research and innovation, the company delivers high-quality roasting, blanching, coating, and frying production lines. Their efficient, automated systems ensure precision, reliability, and long-term performance, helping businesses optimize operations and meet evolving market demands.

GoldenMachinery is consistently investing in research and development to enhance the growth and satisfaction of customers seeking improvements in their processing plants, ensuring they keep up with evolving market demands.

By selecting top-quality components and materials, implementing stringent quality control throughout the manufacturing process, and relying on a highly skilled technical team, we deliver high-standard products that meet the needs of the most demanding markets. Every part of the production chain is carefully optimized and rigorously tested to guarantee maximum precision, efficiency, and long-lasting performance.

Peanut Butter Production Line

Peanut butter production line is designed to efficiently process raw peanuts into creamy or chunky peanut butter. It integrates stages like roasting, grinding, mixing, cooling, and packaging to ensure consistent quality and high throughput.

Peanut Coating Processing Line

Peanut Coating Processing Line starts with raw peanut kernels and features a fully automated process including syrup mixing, coating, forming, roasting, seasoning, and cooling. The line ensures consistent, even coating with precise control, delivering high-quality, flavored peanuts ready for packaging.

Peanut Roasting Blanching Line

Peanut Roasting Blanching Line uses PLC control, handling roasting, whole & split blanching process. It ensures precise temperature control, uniform roasting, effective skin removal, and minimal manual effort for consistent, high-quality output.

Fried Peanut Production Line offers a practical, stable solution for fried peanuts production, using either batch or continuous fryers to achieve consistent results. This line’s reliable performance and ease of use make it ideal for efficient peanut processing.

Why Choose Golden Machinery?

At Golden Machinery, customer first, we prioritize understanding and meeting your unique needs, ensuring that every interaction and solution is tailored.

We stand by our promises and commitments, ensuring transparent and trustworthy interactions with every client. We believe in earning your trust through consistent reliability.

Our team of experts is always available to ensure your operations run smoothly and efficiently, providing peace of mind and immediate assistance whenever needed.

How we work

Simple Step to Choose Proper Peanut Processing Line

Ready to enhance your production? Follow the below steps to consult with our experts and see how our machines can meet your needs!

1

Define Your Processing Purpose

Establish Project Capacity

Confirm Configuration of Whole Line

Finalize Design & Proposal

inquiry Now

Get Free a Quote.

We’d love to hear from you! Send us a message using the form opposite, or email us.